CNC MACHINING

CNC Machining Services

CNC Milling

From rapid prototyping to custom production runs, take advantage of quality 3-axis, 4-axis, and full 5-axis CNC milling for highly accurate and quality CNC milling products. LN offers quality CNC milling services to help transform your designs into complex geometric shapes.

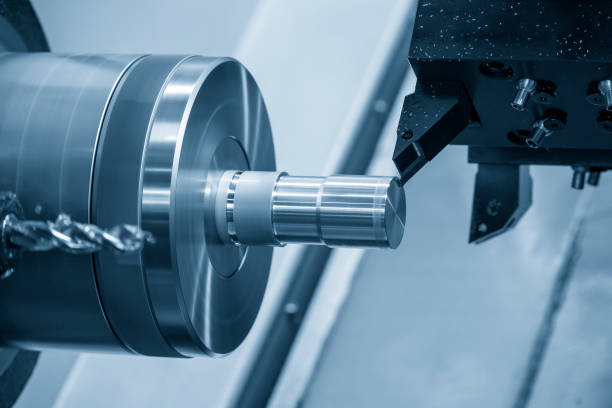

CNC Turning

Our precision CNC turning lathes provide low-cost parts for simple and complex cylindrical geometries. We also use Live tooling to create precise, complex geometries for features like axial and radial holes, grooves, slots, and flats,which makes us can easily and efficiently produce tight tolerance parts.

Our CNC Machining Standards

| CNC Machining Tolerances and Standards | ||

|---|---|---|

| With precision CNC machining services, LN-Machining is your ideal partner to create precision machined prototypes and parts. Our standard CNC machining tolerances for metals is ISO 2768-f and for plastics is ISO 2768-m. We can also achieve special tolerances as long as you indicate your requirements on your drawing. | ||

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 900×550 mm | 800×300 mm |

| 35.43×21.65in. | 31.5×11.81 in. | |

| Minimum Part Size | 4×4 mm | 1.5×q.5mm |

| 0.1×0.1 in. | 0.06×0.06 in. | |

| Minimum Feature Size | Φ 0.50 mm | Φ 0.50 mm |

| Φ 0.00197 in. | Φ 0.00197 in. | |

| Standard Tolerances | Metals: ISO 2768-f | Metals: ISO 2768-f |

| Plastics: ISO 2768-m | Plastics: ISO 2768-m | |

| Linear Dimension | +/- 0.025 mm | +/- 0.025 mm |

| +/- 0.001 in. | +/- 0.001 in. | |

| Hole Diameters | +/- 0.025 mm | +/- 0.025 mm |

| +/- 0.001 in. | +/- 0.001 in. | |

| Shaft Diameters | +/- 0.025 mm | +/- 0.025 mm |

| +/- 0.001 in. | +/- 0.001 in. | |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter |

| Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 5 mm or more, depth: 4-6×diameter | |

| LN-Machining can produce threads of any specification and size required by our customers. | ||

| Text | LN-Machining can use CNC engraving or laser carving to create standard text based on customers’ requirements. | |

| Lead Time | 7 business days | 7 business days |

Quality Promise

100% inspection before shipment

Offer material certifications

Offer inspection reports

All parts inspected using professional testing equipment.(CMM/Projector/Height Gauge)

Quality guaranteed, If fail to meet your specifications, we can process a rework or a refund.

Copyright© 2026Dongguan LiangNeng Machining Co., Ltd.